Temperature and pressure compensated vortex flowmeter

ProductIntroduction

The temperature and pressure compensated vortex flowmeter is a new type of flowmeter developed by using the principle of liquid vibration. It is widely used in the measurement of fluid in petroleum, chemical industry, metallurgy, papermaking and other industries. The flowmeter has no movable parts, high reliability, high precision and long service life. It can measure the instantaneous and cumulative flow of liquid accurately in a wide flow range. It is not affected by the temperature, pressure, viscosity and composition of the medium, and it is not blocked, not stuck, not easy to scale, high temperature and high pressure, safe and explosion-proof. It is suitable for harsh environment. The flow score integral display and remote transmission display, and can output pulse signal or current signal to connect with PLC control system.

Three, temperature and pressure compensated vortex flowmeter flow range table

Table 1, liquid and gas (unit: m) Three /h)

Path (DN) | Liquid flow range (M Three /h) | Output frequency range (Hz) | Gas flow range (M Three /h) | Output frequency range (Hz) |

Fifteen | 1.2 to 6.2 | 90~900 | 5~25 | 265~2640 |

Twenty | 1.5 to 10 | 40~396 | 8~50 | 218~1982 |

Twenty-five | 1.6 to 16 | 32~325 | 10~70 | 172~1420 |

Thirty-two | 2~20 | 20~250 | 15~150 | 130~1350 |

Forty | 2.5 to 25 | 13~130 | 22~220 | 115~1147 |

Fifty | 3.5 to 35 | 9~93 | 36~320 | 96~854 |

Sixty-five | 6~60 | 8~82 | 50~480 | 61~583 |

Eighty | 10~100 | 6~65 | 70~640 | 45~417 |

One hundred | 15~150 | 5~50 | 130~1100 | 43~367 |

One hundred and twenty-five | 25~250 | 5~47 | 200~1700 | 33~290 |

One hundred and fifty | 40~400 | 4~40 | 280~2240 | 27~221 |

Two hundred | 80~800 | 3~33 | 580~4960 | 24~207 |

Two hundred and fifty | 140~1400 | 3~26 | 970~8000 | 20~171 |

Three hundred | 200~2000 | 2~22 | 1380~11000 | 17~136 |

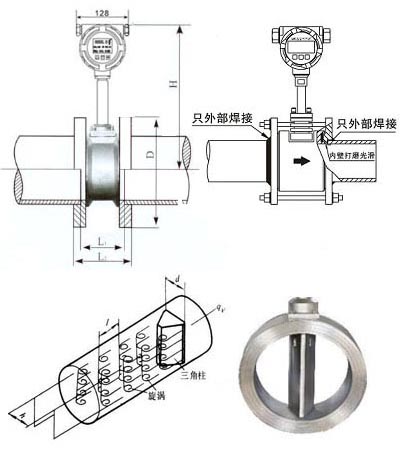

Four, temperature and pressure compensation vortex flowmeter size chart

Path (DN) | L (mm) | H (mm) |  | |||||||||

Ten | Sixty-six | Three hundred and sixty | ||||||||||

Fifteen | Sixty-six | Three hundred and sixty | ||||||||||

Twenty | Sixty-six | Three hundred and sixty | ||||||||||

Twenty-five | Sixty-six | Three hundred and sixty | ||||||||||

Thirty-two | Sixty-six | Three hundred and sixty-five | ||||||||||

Forty | Eighty | Three hundred and seventy | ||||||||||

Fifty | Eighty | Three hundred and seventy-five | ||||||||||

Sixty-five | Ninety-three | Three hundred and eighty-three | ||||||||||

Eighty | One hundred | Three hundred and ninety | ||||||||||

One hundred | One hundred and twenty-five | Four hundred | ||||||||||

One hundred and twenty-five | One hundred and forty-five | Four hundred and seventy | ||||||||||

One hundred and fifty | One hundred and sixty-five | Five hundred | ||||||||||

Two hundred | One hundred and ninety-six | Five hundred and eighty | ||||||||||

Two hundred and fifty | Two hundred and thirty-five | Six hundred and fifty | ||||||||||

Three hundred | Two hundred and fifty-five | Seven hundred | ||||||||||

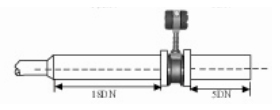

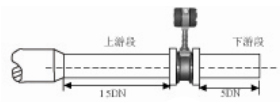

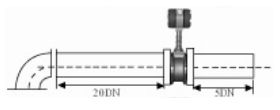

Five, installation sketch map | ||||||||||||

Matters needing attention | Legend | |||||||||||

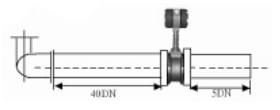

1. installation of expansion pipe For small diameter and large flow, it is necessary to expand the pipe and ensure that the front straight section of the flowmeter is more than 15D, and the straight pipe section is more than 5D. | | |||||||||||

2. installation of shrinkage tube For large diameter and small flow, it is necessary to install the shrink tube while ensuring that the front straight section of the flowmeter is more than 15D, and the straight pipe section is more than 5D. | | |||||||||||

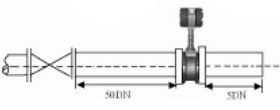

3. installation of elbow pipe If the front end of the flowmeter has a 90 degree elbow or a T type joint, ensure that the straight straight section of the flowmeter is equal to or equal to 15D, and the straight pipe section is equal to or equal to 5D. | | |||||||||||

4. installation of two bends on the same plane. If the front end of the flowmeter has two 90 degree elbows, ensure that the front straight section of the flowmeter is more than 20D, and the straight pipe section is more than 5D. | | |||||||||||

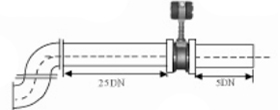

5. installation of two curved pipes in different planes If the front end of the flowmeter has two 90 degree elbows, ensure that the front straight section of the flowmeter is more than 25D, and the straight pipe section is more than 5D. | | |||||||||||

6. installation of regulating valve If the regulator is needed before and after the flowmeter, ensure that the front straight section of the flowmeter is more than 25D, and the straight pipe section is more than 5D. |  | |||||||||||

L six, product selection | ||||||||||||

ZM-LUGB | Vortex Flowmeter | |||||||||||

caliber (mm) | Ten | DN10~DN50 (flange type, clamp type, threaded type, pair clip type) | ||||||||||

Fifty | DN50~DN150 (pair clamp, flange type) | |||||||||||

One hundred | DN100~DN300 (flange type, pair clip type) | |||||||||||

Three hundred | DN300 above is inserted. | |||||||||||

Installation mode | B | Pair clamp | ||||||||||

L | Flange connection type | |||||||||||

C | Insertion type | |||||||||||

Compensation mode | nothing | No compensation | ||||||||||

BC | Temperature and pressure compensation | |||||||||||

W | Single temperature compensation | |||||||||||

Y | Single pressure compensation | |||||||||||

Measuring medium | Y | liquid | ||||||||||

Q | Gas | |||||||||||

Z | steam | |||||||||||

temperature range | T1 | Normal temperature (below 120 C) | ||||||||||

T2 | High temperature type (below 250 C) | |||||||||||

Pressure grade | P1 | Atmospheric pressure to 1.6MPa | ||||||||||

P2 | 2.5MPa | |||||||||||

P3 | 4.0MPa | |||||||||||

Material of Ontology | A | carbon steel | ||||||||||

B | 304 stainless steel | |||||||||||

C | 316 stainless steel | |||||||||||

Power supply mode | D | Two wire DC24V 4 to 20mA | ||||||||||

H | Two wire DC24V 4 to 20mA+HART protocol | |||||||||||

C | Battery powered | |||||||||||

Additional options | R | RS485 MODBUS protocol | ||||||||||

M | Pulse output | |||||||||||

B | Explosion protection (ExII CT6) | |||||||||||

Eight. Installation technology of temperature compensated vortex flowmeter.

SendInquiry

English

English

中文

中文 Magyarország

Magyarország Україна

Україна Polska

Polska Россия

Россия T ürkiye

T ürkiye 日本語

日本語 Deutsch

Deutsch